Maintenance programs help ensure safe, reliable, and cost‑effective airplane performance. Boeing works with operators and regulatory agencies to develop and manage maintenance programs for its commercial fleet. As knowledge of airplane performance increases over time, that experience is applied to maintenance programs in the form of new information and optimized requirements. In recent years, Boeing has made significant progress in optimizing maintenance programs by applying statistical analyses of in‑service performance data as part of its work with operators and regulatory agencies.

By Brian McLoughlin, Senior Manager, Maintenance Program Engineering;

Farshad Doulatshahi, Program Manager, Maintenance Program Engineering;

and Jason Onorati, Business Architect, Maintenance Program Engineering

A new statistical tool is designed to ensure safe, reliable, and cost-effective airplane performance, and participation by operators is key.

Boeing has a long history of working with the aviation industry to develop maintenance programs that help ensure the highest safety and operational reliability levels. To further improve these programs, Boeing has implemented a new statistical analysis process. This process analyzes data from every aspect of airplane maintenance lifecycle and uses a series of algorithms and advanced statistical analysis techniques to identify the optimum maintenance intervals for maintenance inspections. This process has been approved for use by the U.S. Federal Aviation Administration, the European Aviation Safety Agency, and Transport Canada Civil Aviation Authority.

This article provides an overview of this new statistical analysis process and how it works and presents examples of how Boeing is applying this process to optimize maintenance intervals for operators.

The continuous process of improving maintenance

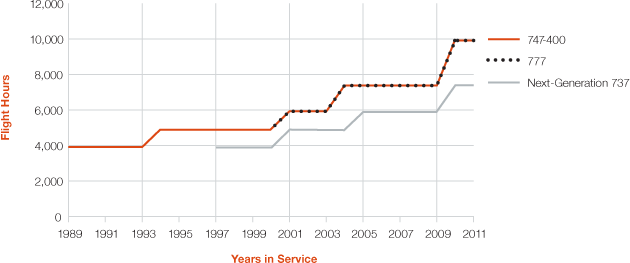

Knowing the optimum interval for scheduled maintenance helps airlines maintain a safe, reliable, and cost-effective operation. Understanding that optimum interval also minimizes airplane out-of-service time due to scheduled maintenance requirements (see fig. 1). Boeing has worked with operators and regulatory agencies for many years to help airlines meet these objectives.

Figure 1: Scheduled maintenance optimization since entry into service

Boeing works continuously to optimize airplane maintenance programs to help ensure safety and reliability and reduce the amount of time an airplane is out of service.

Optimizations of Typical Hangar Scheduled Maintenance Intervals Since Entry into Service

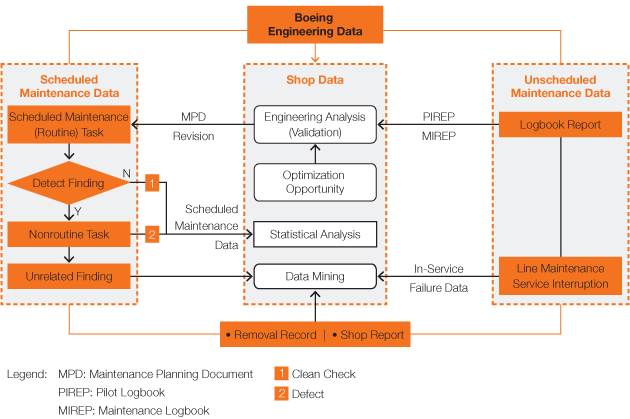

Statistical Analysis for Scheduled Maintenance Optimization (SASMO) is a tool designed specifically to determine optimum scheduled maintenance intervals based on the fleet performance of in-production airplanes. The analysis is based on reliability and cost-management models that allow for an optimum interval to be determined. The SASMO process uses a broad range of maintenance data sources that represent an airplane’s lifecycle (see fig. 2), such as maintenance actions, schedule interruptions, and shop data. The data supporting the analysis is in the industry-sanctioned SPEC2000 format. This comprehensive data analysis helps reduce maintenance cost, increase dispatch reliability, and improve safety.

Figure 2: Data used in the statistical analysis process

Boeing’s analytical tool, Statistical Analysis for Scheduled Maintenance Optimization (SASMO), uses comprehensive data sources to determine optimal scheduled maintenance intervals.

SASMO was developed to efficiently optimize fleet scheduled maintenance requirements and minimize in-service maintenance interruptions. This process helps support fleet dispatch reliability while reducing the cost of maintenance.

SASMO uses a set of algorithms designed to maximize the opportunity to determine the likelihood of system and structural degradation while minimizing in-service maintenance findings related to these tasks. The tool’s statistical process can determine that optimum level in a timely manner.

Optimizing reliability and cost-effectiveness

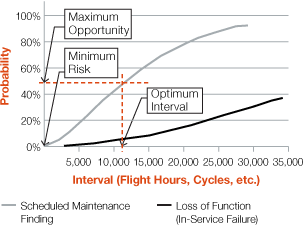

Reliability and risk management. The statistical analysis for task optimization is based on reliability and risk management in terms of the potential impact on the airplane’s operation (see fig. 3).

Figure 3: Establishing scheduled maintenance intervals

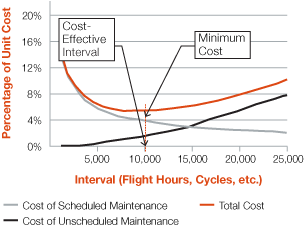

SASMO considers two aspects of task analysis: risk opportunity and economics. The risk opportunity management analysis (left) determines the probability of capturing a minor defect during scheduled maintenance while also measuring the risk of having in-service unscheduled maintenance on the system or structure. The optimum task interval offers the maximum opportunity to capture defects at the earliest stage. Additionally, SASMO can also perform an economic optimization analysis (right) based on the pure economics of performing a scheduled maintenance. The curves show the trend of cost associated with scheduled maintenance compared to unscheduled maintenance. The task should be performed at the point at which total maintenance cost is at a minimum.

| Risk and Opportunity Analysis of a Maintenance Task | Economic Analysis of a Maintenance Task | |

|

|

Cost-effectiveness. The statistical analysis also calculates the point where the cost of a scheduled maintenance inspection and the cost of schedule interruption are minimized.

Implementation of statistical analysis process

The Next-Generation 737 was the first model to implement this statistical analysis process. Based on analyses of maintenance tasks occurring at 4,000 flight hours, 80 percent of scheduled maintenance tasks were escalated, 10 percent remained at their current interval, and 10 percent were de-escalated to minimize unscheduled maintenance events.

Analyses were also performed on the 777 tasks occuring at 7,500 flight hours. As a result of these analyses, 68 percent of task intervals were escalated, 26 percent remained the same, 6 percent were de-escalated, and one task was deleted. While the maintenance interval escalations are significant, these analyses also demonstrate that maintenance optimization can also result in de-escalation, minimizing unscheduled maintenance-related events.

Summary

Boeing’s new SASMO analysis process enables Boeing engineers to determine the optimum intervals for fleet scheduled maintenance programs by using a statistical algorithm to analyze hangar and line maintenance data. The optimum intervals resulting from SASMO analysis process are reflected in Boeing Maintenance Planning Documents and are available for implementation for participating operators. SASMO is designed to support safe, reliable, and cost-effective airplane performance. Participation by operators through data sharing is key to Boeing’s ability to optimize airplane maintenance programs.

For more information, please contact Brian McLoughlin.