| READY, HEAVY, GO!

Colossal

in size, state-of-the art in technology and futuristic in manufacturing,

the Boeing Delta IV Heavy is about to rocket its first payload into orbit.

Launch is set for this fall. Colossal

in size, state-of-the art in technology and futuristic in manufacturing,

the Boeing Delta IV Heavy is about to rocket its first payload into orbit.

Launch is set for this fall.

The 235-foot-tall (72 meters) heavy lifter becomes the next entry in

the Delta family of launch vehicles, joining the dependable Delta II and

other variants of the IV. The Delta IV has a key role in the U.S. Air

Force’s Evolved Expendable Launch Vehicle program—assuring access to space

for the nation’s most critical satellite payloads.

“This mission represents a significant milestone for the nation in that

the Delta IV Heavy is the first large multi-core liquid booster launcher

in the history of the U.S. space program,” said Will Trafton, vice president

and general manager of Boeing Expendable Launch Systems. “From the development

of an all-liquid heavy-lift vehicle, to the robust RS-68 engine, the Delta

IV Heavy was designed, built and tested with all the benefits and skills

from across the Boeing enterprise and our outstanding team of suppliers

and subcontractors.”

FULL STORY >>

How do you hit a bullet

with a bullet?

Although

the easing of tension between superpowers in the late 1980s and early

’90s reduced the likelihood of massive global conflict, a different kind

of threat exists today—the availability of sophisticated missile technology

in many smaller countries. Unfortunately, this missile technology has

proliferated and is in the hands of some who are prepared to use it. Although

the easing of tension between superpowers in the late 1980s and early

’90s reduced the likelihood of massive global conflict, a different kind

of threat exists today—the availability of sophisticated missile technology

in many smaller countries. Unfortunately, this missile technology has

proliferated and is in the hands of some who are prepared to use it.

Among the champions of missile defense is the Patriot missile system—designed

to detect, target and then destroy an incoming missile that may be no

more than 10 to 20 feet long and is typically flying at three to five

times the speed of sound. The latest version of Patriot does what scientists

once said was impossible—hit a missile with another missile, or as some

describe it: “hit a bullet with a bullet.”

FULL STORY >>

TUNNEL VISION

It

doesn’t take long for visitors to the T-38 modification line to discover

that even as outsiders, they’re not exactly going to be feted. It

doesn’t take long for visitors to the T-38 modification line to discover

that even as outsiders, they’re not exactly going to be feted.

Boeing people at the Williams Gateway Airport facility, just outside

Mesa, Ariz., are warm and friendly. They extend sincere greetings. Then

they quickly return to business.

“Everyone is busy,” an observer noted. “The work ethic is amazing.”

With the focus and intensity of surgeons, T-38 teammates systematically

remove and replace the aircraft’s avionics. Their actions are purposeful,

for they are members of a small team with great responsibility. Every

fighter or bomber pilot in the U.S. Air Force will train in T-38s under

their care.

FULL STORY >>

Junkyard DOGS

They’ve

poured sand out of parts from Apaches that patrolled the deserts of Iraq,

Kuwait, Israel and Egypt. They’ve repaired Apache components that were

plagued by bullets and mortar rounds, burned and smashed as they were

put through wars. They’ve

poured sand out of parts from Apaches that patrolled the deserts of Iraq,

Kuwait, Israel and Egypt. They’ve repaired Apache components that were

plagued by bullets and mortar rounds, burned and smashed as they were

put through wars.

They call themselves the “Junkyard Dogs.” This Stage II High Performance

Work Team has the job of transforming parts that “look like junk” into

nearly new condition for replacement on remanufactured Apache Longbows

at Boeing Integrated Defense Systems in Mesa, Ariz.

“We’re like plastic surgeons giving extreme makeovers to Apache parts,”

said Team Lead Bob Johnson. “We see how creative we can get.” In applying

that creativity, the Junkyard Dogs continue to meet the challenge of keeping

within the company’s safety and quality standards.

The 18-person team has nearly 150 years’ combined experience in repairing

composites, sheet metal and mechanical subassemblies. Some team members

have been doing the work for 20 years.

FULL STORY >>

Boeing’s strike force

Before

retuning the Space Shuttle to flight, the Columbia Accident Investigation

Board concluded that NASA needed to develop, validate and maintain physics-based

computer models to evaluate Thermal Protection System damage to the Space

Shuttle from debris impacts. Before

retuning the Space Shuttle to flight, the Columbia Accident Investigation

Board concluded that NASA needed to develop, validate and maintain physics-based

computer models to evaluate Thermal Protection System damage to the Space

Shuttle from debris impacts.

In response, a team of Boeing employees representing Integrated Defense

Systems, Commercial Airplanes and Phantom Works began to pool efforts

to increase understanding and predict the effects of foam, ice and ablators

(insulators that act as a heat shield and help dissipate heat) striking

the orbiter.

“We are running a series of tests and performing analysis to determine

the impact of debris on the orbiter,” said Scott V. Christensen, Boeing

manager for Orbiter Vehicle Engineering and overall lead for the debris

analysis efforts.

FULL STORY >>

All the INFORMATION

wherever you

are

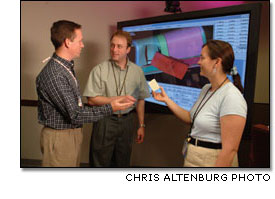

More

than two dozen reporters from major broadcast and print media outlets

gathered at three Boeing sites June 29 for a first-hand look at the power

and potential of network-centric operations. What they saw was a multiscreen,

multisite, multiplatform demonstration of the networks and tools Boeing

uses to model, simulate, and test NCO concepts, programs and solutions. More

than two dozen reporters from major broadcast and print media outlets

gathered at three Boeing sites June 29 for a first-hand look at the power

and potential of network-centric operations. What they saw was a multiscreen,

multisite, multiplatform demonstration of the networks and tools Boeing

uses to model, simulate, and test NCO concepts, programs and solutions.

The event also introduced reporters to the new Boeing Integration Center

East in Crystal City, Va.

“Boeing has invested significantly in the Integration Center, in networking

tools and the various battle laboratories we have across the country,”

IDS President and CEO Jim Albaugh said at the event, which also was broadcast

via video teleconference over the Boeing Intranet. “Using these capabilities,

we’re going to create an information-rich environment to demonstrate how

we are working with our customers to understand the power of a network-centric

approach to the battlefield.”

FULL STORY >>

|