|

These are exciting times in the aviation industry. We’re seeing increased use of composite material for airframe structure, one-piece fuselage sections, advanced systems capabilities, and global partnerships — just to name a few achievements. The Boeing Company is leading the way in leveraging these new technologies and business models — for both our airline customers and the passengers who will soon experience the super-efficient 787 Dreamliner. |

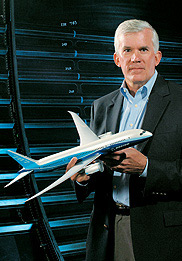

| MIKE BAIR INSIDE ONE OF THE FIRST 787 COMPOSITE FUSELAGE TEST BARRELS, NOW ON DISPLAY AT THE FUTURE OF FLIGHT MUSEUM IN MUKILTEO, WASHINGTON. | Mike Bair Vice President and General Manager, 787 Program |

By focusing hard on the right technologies and working with the best partners, we’re delivering an airplane with breakthrough economics for airlines and a passenger experience superior to any airplane flying. The 787 offers a pleasing interior, unmatched fuel efficiency, and a 30 percent reduction in maintenance costs.

Our emphasis on environmental benefits has been very well received by our customers — beyond even our own expectations. Our new business model of getting design input from financiers allowed for early decisions that affect the lifecycle value of the airplane and will keep the 787 Dreamliner a good investment for many years. Designing and building this airplane with the best domestic and international partners has been key to making us competitive in the marketplace. And offering a family of 787 models (see accompanying chart) enables us to be flexible and meet the different needs of the airlines.

In April, our final assembly factory in Everett, Washington, received the first major 787 structures from our partners around the world. The nose and tail sections, wings, and center fuselage section for the first airplane were delivered using our new Dreamlifter, a modified 747-400 passenger airplane that hauls more cargo by volume than any airplane in the world.

Final assembly began in May, and on July 8, 2007, we premiered the first 787 Dreamliner with a wonderful event shared by employees, airlines, partners, and thousands of others around the world. Seeing the airplane at the Premiere for the first time was a reflection of the hard work of so many people during the past five years. It’s not every day we get to bring a new airplane to market and showcase it to the world!

Now our team is very focused on getting the 787 ready for first flight and flight test. We are installing final systems elements, interiors, and flight-test equipment. The flight-test program, which includes a total of six airplanes, will conclude in May 2008 with the certification of the airplane, followed shortly thereafter by the first delivery of a 787 to launch customer All Nippon Airways (ANA).

In addition to the visible work going on in the Everett final assembly factory, a lot of great work is going on behind the scenes to ensure that we meet our 787 commitments and promises to customers. We are working tirelessly to ensure the airplane is service-ready and the airlines are able to take full advantage of the new technology being built into the 787 to reduce operating costs and maximize revenue flights.

At a series of service-ready conferences recently held around the world, customers were given a detailed look at how to use 787 technology to maximize efficiencies within their maintenance, training, and flight operations. We’ve also issued the first release of the maintenance task cards, recommended spare parts lists, and preliminary flight operations manuals. And we’ve completed the first maintenance training class, which was attended by Boeing Flight Test mechanics.

As of July 31, 47 customers worldwide have ordered 683 airplanes worth more than $110 billion at current list prices, making the 787 Dreamliner the most successful commercial airplane launch in history. And there’s more to come!

Mike Bair

Vice President and General Manager,

787 Program