WORKING WITH ESWAT/IWS

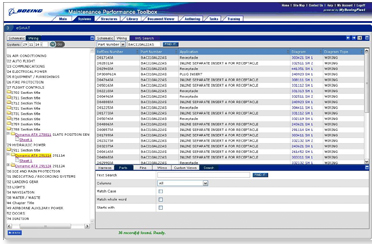

eSWAT/IWS dynamically displays system wiring information to the airline maintenance team. Wiring information is stored in a database which can be accessed through MyBoeingFleet.com. The information can be retrieved as requested by the user and filtered to apply specifically to the airplane being serviced. The data is then formatted and displayed in any combination of wiring diagram, pin listing (within a connector), and/or wire listing (see fig. 2).

|

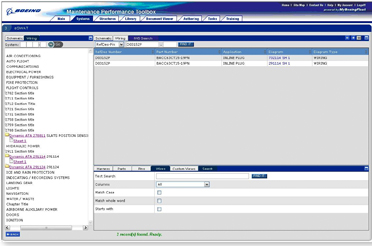

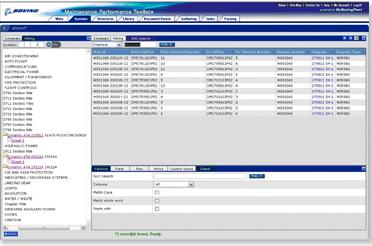

CUSTOMIZABLE VIEWS AND SEARCH CAPABILITY ENHANCE EFFICIENCY Users can customize the tabular view of the data and search on a specific item. In this example, the tabular view gives the airline maintenance team detailed information about a specific part and allows the user to draw a dynamic view of that data, or search repair practices or fault information based on this tabular data. This capability reduces the very large amount of data that would have been present in a traditional wiring data and wiring report to a very small amount of data, enabling the airline maintenance team to quickly isolate the area where work needs to be done and reducing the time required to service the airplane. |

|

eSWAT/IWS eliminates the need to sort through multipage foldouts and interpret system configuration information. Locator graphics, connector pin arrangement graphics, parts listings, and drawing notes are always readily available.

To access the tool, the user enters the airline’s airplane tail number and specifies through the table of contents which wiring system to display. The tool draws a wiring diagram and provides detailed report data. Graphical icons enable users to quickly locate key functions. While researching the wiring, harness, or electrical component to be studied, the user can zoom in or out, compare one airplane configuration to another, and print any part, display, or information for use in troubleshooting or repairs. eSWAT/IWS is integrated into the rest of the 787 maintenance information.

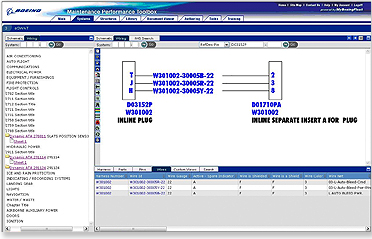

Airline maintenance teams can use eSWAT to view a very small subset of a much larger drawing. This drawing displays only the connectivity between an inline plug and the three wires leading to an insert for a plug. This very basic view of a very small subset of a complex electrical system can dramatically reduce the team’s research time while maintaining accuracy.