CAUSES OF WHEEL/TIRE ASSEMBLY EXPLOSIONS

Airplane wheel/tire assemblies are inflated to high pressures, often in excess of 200 pounds per square inch (psi). Because the pressure in a nitrogen bottle or tire-servicing cart can be as high as 3,000 psi, connecting the nitrogen source directly to the wheel without a regulator subjects the wheel to sudden high pressure that can exceed the design limits for the wheel, the wheel tie bolts, or the tire. Consequently, the wheel, the wheel tie bolts, or the tire can explode and become projectiles (see fig. 1, above), causing severe injuries, dismemberment, or death.

In most of the reported cases of related injuries, the wheel/tire assembly that exploded was a nose wheel on a smaller-configuration airplane such as a 737 or DC-9. These tires present a greater risk because their smaller size means they reach dangerous pressures faster than the tires on main landing gear.

TIRE INFLATION PRECAUTIONS

Whenever an airplane tire is being serviced, three layers of protection are normally in place to protect maintenance workers from wheel fracture:

- A pressure regulator on the nitrogen supply.

- A pressure relief valve on the tire inflation tool.

- An overinflation pressure relief (OPR) valve installed in the wheel.

Pressure regulator on the nitrogen supply. Maintenance personnel should never attempt to inflate a wheel/tire assembly in any maintenance or shop location without a regulator between the pressure source — such as a tire-servicing bottle or cart — and the inflation valve on the wheels. It is essential that operators ensure regulated nitrogen sources are correctly used. Boeing also recommends operators have back-up protection (such as additional regulation or pressure-relief devices) installed in all high-pressure nitrogen sources in case the primary regulator is not adjusted correctly or fails to properly regulate. Procedures for inflating the wheel/tire assembly when it is installed on the airplane are located in Chapter 12 of the Airplane Maintenance Manual (AMM).

Pressure relief valve on tire inflation tools. Because many inflation valves on airplane wheels are similar to automotive valve designs, automotive tools are frequently used for airplane wheels. However, many Boeing AMMs specify a tool for tire inflation that incorporates a pressure relief device designed to release at a pressure slightly higher than the tire service pressure, providing an additional layer of protection if the nitrogen source is inadvertently at high pressure (see fig. 2).

|

|

| TIRE INFLATION TOOL Figure 2 A tire inflation tool such as this adds another level of protection that can help prevent over-pressurization of the wheel/tire. |

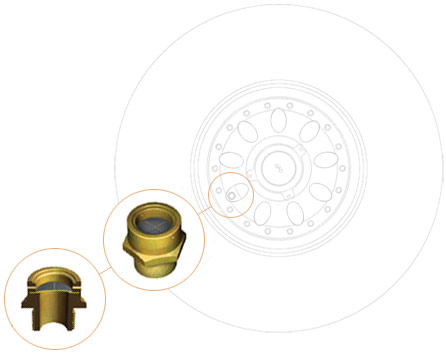

OPR valve installed in the wheel. The risk of explosion increases greatly on wheels that are not equipped with an OPR valve. An OPR valve is a device similar to that shown in figure 3. It is included in many wheel assemblies to limit the pressure in the wheel/tire assembly. If the pressure in the wheel exceeds a predetermined value, a disk in the OPR valve will rupture, allowing the gas to escape while reducing the pressure in the wheel before it can fracture. After the disk ruptures, the gas in the wheel exits through the OPR valve. The valve is designed so that when the disk ruptures, the gas will exit from the wheel faster than it can be supplied from the pressure source.

Certain older wheels do not include this valve. As a result, Boeing recommends the following retrofits:

DC-9/MD-80 operators: Boeing recommends retrofitting an OPR valve into all nose wheels per McDonnell Douglas Air Operator Letter 9-2274, "Nose Landing Gear Wheel Assembly Failure," dated July 21, 1992.

737-100/-200 operators: Boeing recommends retrofitting the OPR valve into all nose wheels per Honeywell Service Bulletin 2601045-32-002, "Modification of the 737-100/-200 Nose Wheel Assembly P/N 2601045-2 Into Assembly P/N 2601045-3, for Installation of a Safety Relief Valve," dated August 31, 2000.