INTELLIGENT, GRAPHICAL USER INTERFACES STREAMLINE ACCESS TO SPECIFIC MAINTENANCE INFORMATION

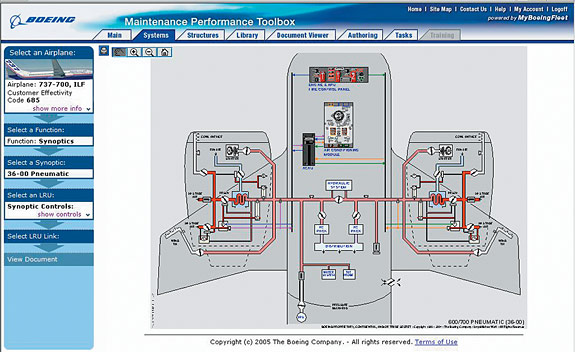

The Maintenance Performance Toolbox uses 2D schematics of airplane systems that enable point-and-click access to all of the information related to a specific airplane location or component (see fig. 2).

MAINTENANCE PERFORMANCE TOOLBOX SCREEN

Figure 2

The Maintenance Performance Toolbox uses intelligent graphical user interfaces to streamline access to specific maintenance information and improve the efficiency and effectiveness of maintenance and engineering staff.

| SPECIFICALLY DESIGNED TO IMPROVE MAINTENANCE PERFORMANCE | ||

|

||

| A new maintenance support solution to improve the efficiency and effectiveness of maintenance and engneering staff | Tools deployed stand-alone or combined to create “solutions” that meet specific operational needs | |

| Delivered as a hosted service, securely accessible globally | Intelligent graphical user interfaces to streamline access to specific maintenance information | |

|

||

This intelligent graphical user interface allows maintenance personnel to quickly locate information about the exact area of the airplane that requires maintenance. For instance, instead of spending time searching manually or electronically through the Fault Isolation Manual to troubleshoot the problem and then through the Airplane Maintenance Manual (AMM) for repair information, maintenance personnel can click on 2D airplane system diagrams to retrieve line-replaceable-unit information, including maintenance procedures, troubleshooting information, parts data, wiring diagrams, maintenance tips, in-service activity reports, and service letters.

This same system can be used to locate troubleshooting information associated with central-maintenance-computer messages, fault codes, cabin faults, and flight deck effects. It also enables retrieval of part information directly from the airplane Illustrated Parts Catalog (IPC).

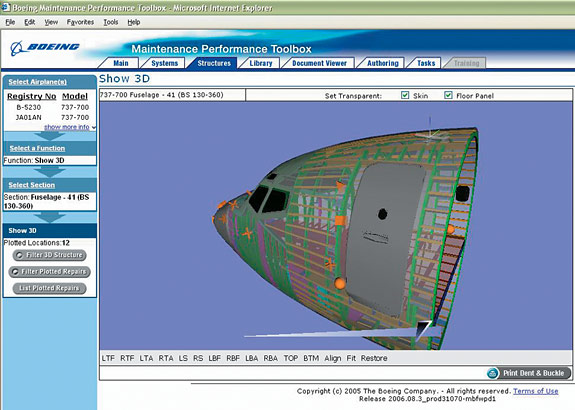

The location of structural damage can be indicated graphically on a 3D airframe model (see fig. 3). Clicking on a plotted “incident” provides information about that particular incident. Repair information is structured to standardize record contents and format. This enables operators and maintenance organizations to:

- Comply with recordkeeping requirements of regulatory authorities.

- Retain airplane values during transfers of airplane ownership by having proof-of-repair records.

- Share repair information for teams in different geographic locations in real time.

3-D AIRFRAME MODEL

Figure 3

Three-dimensional airframe models make it easy to document and research structural incidents. Incidents can be plotted graphically to show exactly which part of the airframe was affected. Clicking on an incident brings up detailed information about it.

| STREAMLINES ACCESS TO MAINTENANCE INFORMATION | ||

|

||

| Role-based to align with work activities (e.g., structures, maintenance control, engineering, maintenance planning) to meet information needs | Graphical user interface to streamline access to information across all documentation | Training information deeply integrated and available as-needed |

| Intuitive user interface and common look and feel to minimize user learning curve | Distributed staff and service partners work from a common information set | |

|

||

Because the Maintenance Performance Toolbox emphasizes a role-based design, it aligns with work activities (such as structures, maintenance control, engineering, and maintenance planning) to meet operators’ information needs. The graphical user interface streamlines access to information across all documentation. And the intuitive user interface and common look and feel minimize user learning curves.