| Regardless of airplane model, tail strikes can have a number of causes, including gusty winds and strong crosswinds. But environmental factors such as these can often be overcome by a well-trained and knowledgeable flight crew following prescribed procedures. Boeing conducts extensive research into the causes of tail strikes and continually looks for design solutions to prevent them, such as an improved elevator feel system. Enhanced preventive measures, such as the tail strike protection feature in some Boeing 777 models, further reduce the probability of incidents. |

by Capt. Dave Carbaugh, Chief Pilot, |

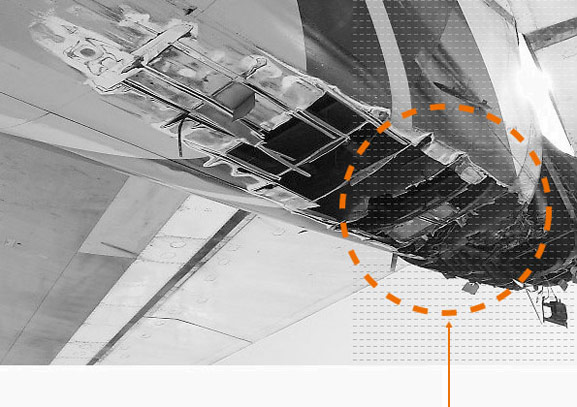

Tail strikes can cause significant damage and cost operators millions of dollars in repairs and lost revenue. In the most extreme scenario, a tail strike can cause pressure bulkhead failure, which can ultimately lead to structural failure; however, long shallow scratches that are not repaired correctly can also result in increased risks. Yet tail strikes can be prevented when flight crews understand their causes and follow certain standard procedures.

Two vital keys to prevention are raising awareness of tail strikes among flight crews and including tail strike prevention in standard training procedures. It’s also important to promote discussion about tail strikes among members of the flight crew as part of takeoff and landing briefings, particularly when strong wind conditions are present.

This article:- Provides an overview of tail strikes and how Boeing is addressing them.

- Examines tail strike causes and prevention.

- Discusses operations in strong gusty winds.

- Reviews training recommendations and preventive measures.

TAIL STRIKES: AN OVERVIEW

A tail strike occurs when the tail of an airplane strikes the ground during takeoff or landing. Although many tail strikes occur on takeoff, most occur on landing. Tail strikes are often due to human error.

Tail strikes can cause significant damage to the pressure bulkhead. Failure of the pressure bulkhead during flight can cause a catastrophic event if the flight continues while pressurized. Tail strikes are expensive, too. During a safety investigation, one airline reported that a single tail strike cost its company $12 million in repair cost and loss of revenue during the repair.

Boeing has done design work to reduce tail strikes, including implementing an improved elevator feel system in some airplanes. For example, the

In addition, some 777 models incorporate a tail strike protection system that uses a combination of software and hardware to protect the airplane. And some models of the 737, 767, and 777 have a tail skid that prevents damage from most takeoff tail strikes. However, these devices do not guarantee protection for landing tail strikes and some takeoff tail strikes. They also reduce tail clearance distances.

Many of the longer-bodied Boeing airplanes use relatively higher speeds than their shorterbodied major models (e.g., the