The Next-Generation 737 Performance Improvement Package (PIP) combines aerodynamic and engine performance improvements to reduce fuel burn by up to 2 percent.

By Dennis Tesch, 737 Systems Senior Manager, Performance Improvement Package Program Manager

The Next-Generation 737 PIP lowers operational costs while improving the environmental signature of the airplanes that use it.

Boeing has developed a number of performance enhancements to the Next-Generation 737 that reduce fuel consumption and emissions. Elements of the PIP have been introduced gradually on the 737 since early 2011. Boeing has delivered more than 490 Next-Generation 737s with a PIP.

This article reviews the elements of the Next-Generation 737 PIP and the aerodynamic and propulsion efficiency improvements that have resulted in reduced fuel burn and emissions. It also discusses the expected benefits to the operator.

Components of the Next-Generation 737 PIP

The Next-Generation 737 PIP comprises both drag reduction and propulsion efficiency components.

Drag reduction components are aerodynamic-shaped anti-collision (AC) lights, refined wing control surfaces, spoiler trailing edge gap reduction, ski-jump wheel-well fairings, and environmental control system (ECS) inlet/exhaust modulation.

Greater propulsion efficiency results from enhancements to the CFM International (CFM) engine and improvements to the exhaust system.

Drag reduction improvements

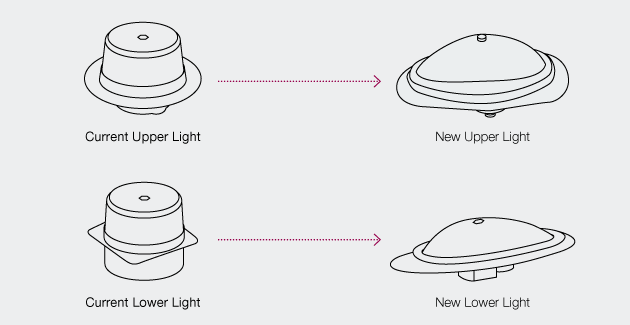

Aerodynamic AC lights. Replacing the upper and lower red AC light assemblies with a more aerodynamically designed shape reduces airplane drag (see fig. 1). The upper skin was revised, and no electrical interface changes were required to accommodate the new AC lights.

Figure 1: Aerodynamic-shaped anti-collision (AC) lights

New AC lights (right) are more aerodynamic than the previous lights (left).

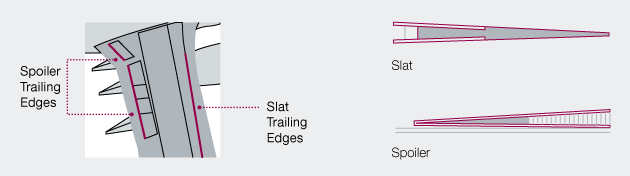

Refined wing control surfaces. Reducing the thickness of the spoiler trailing edge reduces drag caused by the aft-facing step on the trailing edge of the spoilers. The trailing edge’s extruded aluminum filler has been replaced with a machine-tapered filler. A reduction in the slat trailing edge’s thickness further reduces drag by reducing the thickness of the trailing edge wedge (see fig. 2).

Figure 2: Streamlined slat and spoiler trailing edges

Trailing edges on the spoiler (left) and slat (right) are 60 percent thinner to reduce drag.

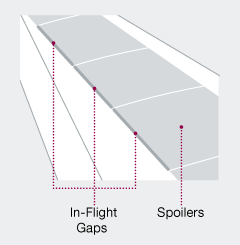

Spoiler trailing edge gap reduction. This change reduces drag by reducing the gap between spoilers 2, 3, 4, 9, 10, and 11 and their respective flaps (see fig. 3). Analysis and flight tests have shown these new gaps meet stability and control requirements.

Figure 3: Spoiler trailing edge gap reduction

Adjusting the smaller gaps results in reduced drag.

| Spoiler Panels | Previous Gap | New Gap |

|---|---|---|

| 1, 12 | 0.07 in (0.18 cm) | 0.08 in (0.20 cm) |

| 2, 11 | 0.32 in (0.81 cm) | 0.10 in (0.25 cm) |

| 3, 10 | 0.27 in (0.69 cm) | 0.065 in (0.165 cm) |

| 4, 9 | 0.27 in (0.69 cm) | 0.065 in (0.165 cm) |

| 5, 8 | 0.06 in (0.15 cm) | 0.065 in (0.165 cm) |

| 6, 7 | 0.05 in (0.13 cm) | 0.08 in (0.20 cm) |

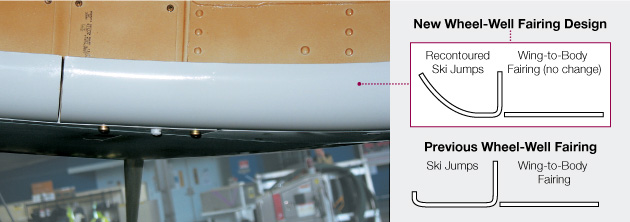

Wheel-well fairings. The five aft wheel-well fairing assemblies have been recontoured to smooth the airflow near the main landing gear, reducing airplane drag (see fig. 4).

Figure 4: Ski-jump wheel-well fairings

The PIP includes five new contoured panels on the aft side of the wheel wells.

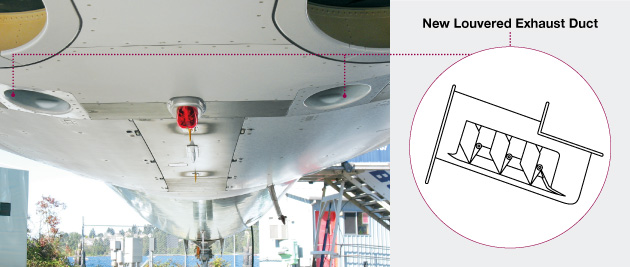

New ECS exhaust vent. The PIP also reduces drag by modifying the existing ram air inlet systems and adds new modulated ram air exhaust systems associated with the left and right air-conditioning packs (see fig. 5). The previous ram air inlet actuators have been replaced by new “smart actuators” that allow position feedback and communicate with the added ram air exit actuators. The new smart actuator is mounted at a slightly different orientation at the inlet than the current actuator, and the ram air exit has been changed from a plain duct opening to a duct with a series of three exit louvers. The exit louvers are actuated by a combination of shafts and linkages that are driven by the added exit actuators. To accommodate installation, structural changes have been made forward of the wheel wells on both sides of the airplane.

Figure 5: Newly configured exhaust vents designed to reduce drag

The system — inlet and exit — is tuned to open and close together at a very specific relationship to optimize thrust recovery of the air exiting the exhaust louvers, reducing fuel burn of the airplane.

Propulsion efficiency improvements

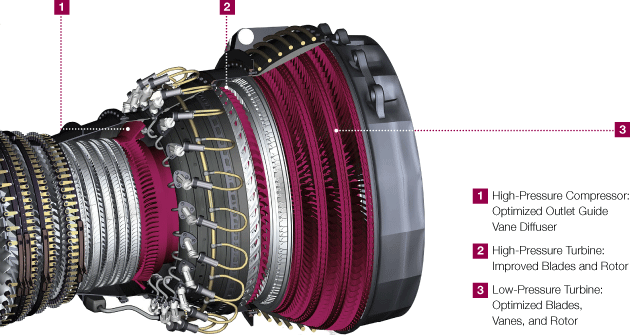

The propulsion system improvements include changes to both the engine (see fig. 6) and exhaust system. The engine changes include:

- The diffuser contours of the high-pressure compressor (HPC) outlet guide vane (OGV) are optimized to improve the diffuser-area ratio and reduce pressure losses. The OGV replaces the two-dimensional airfoil with a three-dimensional design.

- A new high-pressure turbine (HPT) incorporates modified blades for aerodynamic improvements that increase efficiency and durability. The HPT rotors have been modified to accept a reduced blade count, from 80 to 76.

- A new low-pressure turbine (LPT) incorporates new optimized blades, vanes, and rotors. The number of blades and vanes has been reduced by approximately 9 percent overall. New disks and retainers match the blade count, and new case and shrouds match the new axial staggering.

Figure 6: CFM engine changes

Changes to the CFM engines improve propulsion and reduce fuel consumption.

The new CFM56-7BE (PIP) engines are interchangeable and intermixable with previous CFM56-7B and CFM56-7B3 Next-Generation 737 GE engines.

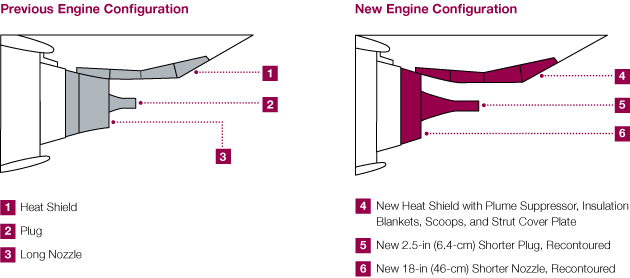

Changes to the exhaust system (see fig. 7) include:

- A new primary nozzle is approximately 18 inches (46 centimeters) shorter than the previous engine and has recontoured lines for improved nozzle coefficients and losses. An acoustically treated honeycomb lining incorporated into the primary nozzle’s inner wall ensures no increase to community noise occurs as a result of this efficiency improvement.

- A new strut aft fairing heat-shield assembly has been incorporated with heat shield blankets and an inboard plume suppressor. These components will reduce aft fairing thermal distress and are required to accommodate the short nozzle configuration.

- The primary plug has been recontoured for improved plug coefficients and losses. An oil drain pan and tube are installed to reduce oil pooling within the plug.

Figure 7: Engine exhaust system reconfigured to improve performance

The new engine exhaust configuration reduces aft fairing thermal distress.

Benefits to operators

For a Next-Generation 737 operation carrying the same payload and flying the same route as a non-PIP airplane, the PIP-equipped version will fly with reduced fuel consumption and carbon dioxide and nitrous oxide emissions.

The engine improvements result in:

- Improved fuel burn.

- Engine maintenance costs reduced up to 4 percent for the highest thrust rating — the higher the thrust rating, the higher the maintenance cost improvement. PIP engines are operationally transparent to the flight crew; there are no changes to normal flight crew procedures or airplane flight manual performance relative to previous engines.

More than a year after the first Next-Generation 737 PIP airplane was delivered, operators have validated the benefits of the package, reporting fuel burn reductions of up to 2 percent. Improving fuel efficiency by this amount can save more than US$120,000 annually in fuel cost per airplane and reduce the carbon footprint.

| Improvement | Post-Delivery Modification | Modification Process |

|---|---|---|

| Slats | Yes | Replacement parts fully interchangeable with existing slats. |

| Spoilers | Yes | Replacement parts fully interchangeable with existing spoilers; rigging change required for spoiler trailing edge gap reduction. |

| Wheel-well fairings | Yes | Replacement parts fully interchangeable with noncontoured fairings. |

| Anti-collision lights | Yes | New lower light shares common attach point, fastener pattern, and electrical interface with existing lights and are interchangeable. Upper light is not interchangeable because a crown skin change is needed. |

| ECS exhaust vent | No | No modification available. |

| CFM56-7BE engines | Yes | Interchangeable with previous engines. |

| Engine exhaust system | Yes | Nozzle and plug are interchangeable parts, but only specific combinations are allowed, and both require the new strut heat shield. |

Summary

The Next-Generation 737 PIP demonstrates Boeing’s commitment to improving existing in-service airplanes. The package lowers operational costs while improving the environmental signature of the airplanes that use it.