The successful process for assessing line operations safety in the airline flight environment has now been extended into the areas of ramp and maintenance operations. The ramp line operations safety assessment (LOSA) and maintenance LOSA are intended to enhance ramp and maintenance safety, respectively, through voluntary, peer-to-peer observations under strict nonpunitive conditions.

By William Rankin, Ph.D., Technical Fellow, Maintenance Human Factors, and

Bill Carlyon, Program Manager, Environment, Health and Safety Support

The tools for ramp LOSA and maintenance LOSA include a ready-to-use database and data analysis software that stay with the operator.

Flight LOSA has proved its value as a predictive safety process in airline flight operations. The assessment process is based on peers observing peers during normal operations. Observation data are kept anonymous, there is a clear no-punishment policy, and the observations can be used as a basis for making safety improvements.

Recently, the Airlines for America (A4A) Joint Engineering, Maintenance & Material Council and Safety Council Human Factors Task Force has extended the LOSA concept to ramp and maintenance operations. The task force included A4A member airlines, Boeing representatives, ground service providers, and members of the U.S. Federal Aviation Administration (FAA). The term “assessment” was purposefully chosen instead of “audit” because the task force wanted to separate LOSA from the traditional airline quality control or safety audit processes.

This article provides a summary of the LOSA process and how to implement the process using the observation tools, observer training materials, and database software available for ramp LOSA and maintenance LOSA.

The LOSA process

Flight LOSA has been demonstrated to be a valuable safety tool. It was developed as a joint endeavor between the University of Texas at Austin (UTA) and Continental Airlines. LOSA is based on the UTA Threat and Error Management (TEM) model, which hypothesizes that threats and errors are integral parts of daily flight operations and must be managed. Therefore, observing the management or mismanagement of threats and errors during normal operations can provide a clear picture of actual performance. Flight LOSA has been a very successful program with most large international airlines using the process and reporting safety benefits from the program.

The ramp LOSA effort was initiated at Continental Airlines in early 2007. Its LOSA implementation contributed to a dramatic decrease in airplane ground damage. This caught the industry’s attention, which led to the creation of the A4A Human Factors Task Force. Through this task force, the industry and government continue to partner closely to improve the safety of ramp and maintenance operations by developing LOSA tools. The available LOSA materials describe the process; provide the ramp LOSA and maintenance LOSA observation tools, database software, and training materials; and list the active industry partners.

Like flight LOSA, ramp LOSA and maintenance LOSA are based on the TEM model and offer airlines similar benefits (see fig. 1). Ramp LOSA and maintenance LOSA are centered on observations made during normal operations by trained observers with a goal of stopping errors from occurring that lead to injuries and damage to equipment or airplanes. LOSA is a voluntary process that is nonthreatening and nonpunitive.

Figure 1: Benefits of line operations safety assessments (LOSA)

Ramp LOSA and maintenance LOSA offer airlines a number of benefits that can improve safety and enhance existing procedures.

| Benefits of LOSA | |||||||

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

| Identify and Manage Threats |

Assess Training Effectiveness | Check Quality/Usability of Procedures | Involve Employee Groups | Complements Existing Safety and Quality Assurance Programs |

Assess Safety Margins |

Baseline for Organizational Change | Identify and Manage Errors |

Observations of ramp and maintenance activities enable the airline to acquire data about actual day-to-day safe and at-risk behaviors in real-time, normal operations; discover procedural or systemic flaws that might lower safety margins; determine good practices that are in place; and provide baseline data that can be used to assess the effectiveness of safety interventions that were implemented to correct the at-risk behaviors.

Key LOSA characteristics

LOSA is characterized by observations made during normal ramp operations or normal maintenance operations. Data are collected anonymously and confidentially by trusted and trained observers from the ramp or maintenance staff, respectively. The effort is sponsored jointly by management and ramp or maintenance staff, and participation is voluntary.

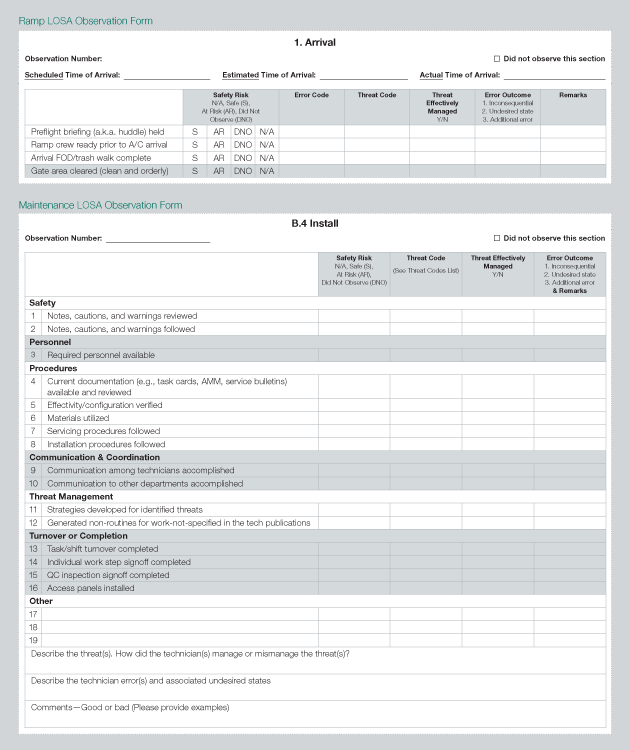

Although the philosophy and principles for ramp LOSA and maintenance LOSA are the same as for flight LOSA, the systems used are very different from each other. Flight LOSA relies on trained pilots using open-ended text to record observations. Ramp LOSA and maintenance LOSA have structured observation checklists that are used by an airline’s own staff (see fig. 2). The tools developed for ramp LOSA and maintenance LOSA include a ready-to-use database and data analysis software that are kept with the operator. There is no need for outside data storage and analysis. This ensures that company data are secure and that analysis does not require external consultants.

Figure 2: Ramp LOSA and maintenance LOSA observation forms

The ramp LOSA observation form (top) and maintenance LOSA observation form (bottom) provide observers with clear indications of the activity that should be observed and recorded.

Data verification roundtables are used to reveal any data inaccuracies due to differences in opinion about company policies, processes, and procedures by the LOSA observers. The results of the observations are provided to the ramp or maintenance crews in summary form. Then data-derived targets for improvement are established, interventions are put in place to address these targets, and additional observations are carried out to determine if the interventions brought about the desired changes.

Threats and error management

The foundation of LOSA is the TEM model. In this model, the ramp or maintenance worker is to actively identify threats, develop strategies to manage the threats so that they do not lead to errors, manage the errors that do occur, and learn from past errors in order to anticipate future threats and ultimately manage the threats better in the future to prevent errors.

Threats. Threats are any condition that increases the complexity of the operations and if not managed properly can decrease the safety margin during ramp or maintenance operations. There are two types of threats:

- External threats are threats outside control, including weather, a late gate change, lack of the correct tool to do a maintenance task, pressure from management, and a poorly written task handover log entry.

- Internal threats are threats within control, including fatigue, preoccupation (i.e., loss of situation awareness), time pressure, lack of training, and disregard for following processes and procedures.

Errors. Errors are the mistakes that are made when threats are mismanaged. It is an action or inaction by the ramp or maintenance crew that leads to deviations from organizational or crew intentions or expectations. There are five categories of error:

- Intentional noncompliance error. Willful deviation from regulations and/or operator procedures.

- Procedural error. Deficient execution of regulations and/or operator procedures. The intention is correct, but the execution is flawed. This also includes errors in which the crew forgot to do something. It may only differ from an intentional noncompliance error based on intention.

- Communication error. Miscommunication, misinterpretation, or failure to communicate pertinent information, e.g., among the ramp or maintenance crew, between the ramp or maintenance crew and an external agent (e.g., flight crew), or between work shifts.

- Proficiency error. Lack of knowledge or psychomotor skills (e.g., driving a belt loader or lockwiring a component on an engine).

- Operational decision error. Decision-making error that is not standardized by regulations or operator procedures and that unnecessarily compromises safety. Three conditions must exist to have this error:

- The decision was selected by the crew from two or more options.

- The decision was not shared among crew members.

- The decision selected by the crew was not adequately evaluated even though the crew had sufficient time.

Types of error responses. LOSA considers three possible responses by crews to errors:

- Trap or mitigate. An error is detected and managed so that the result no longer affects safety or performance.

- Exacerbate. An error is detected, but the crew actions or inactions cause the situation to worsen.

- Fail to respond. An error is undetected or ignored by the crew.

Error outcomes. Crew responses to an error can result in one of three outcomes:

- Inconsequential. The risk caused by the error does not produce any negative consequence.

- Undesired state. The error puts staff or equipment in a situation where safety is compromised. This occurs when the ramp or maintenance crew exposes people, equipment, or airplanes to unnecessary risk (e.g., improperly using equipment). An undesired state is different from an error in that it is a condition or situation that results from an error. It may also result from external threats.

- Additional error. The mistake leads to an additional error.

Conducting a ramp LOSA or maintenance LOSA

A ramp LOSA is carried out during an airplane turn. Since so much is happening in a short time frame, a ramp LOSA is typically carried out by a team of two or three trained ramp peer observers. Maintenance LOSAs are typically conducted by one trained maintenance peer observer. Two or more observers may be used for complex tasks (e.g., engine change). Observers need to be vigilant to the possibility that years of exposure may have desensitized them to ongoing threats and errors.

The ramp LOSA observation form has 11 sections:

- Arrival.

- Downloading.

- Lavatory and potable water service.

- Catering.

- Cleaning service.

- Fuel service.

- Uploading.

- Departure.

- Airplane maintenance.

- Deice and anti-ice.

- Pilot walk-around.

It is up to the organization to determine what is to be observed. For example, a decision could be made not to observe the cleaning service. Also, the observations of airplane maintenance or deice and anti-ice can only be made when the conditions warrant these tasks. Each section of the observation form provides observers with specific observations that should be made and recorded.

The maintenance LOSA observation form has nine sections:

- Planning.

- Prepare for removal.

- Removal.

- Prepare to install.

- Install.

- Installation test.

- Close-up and complete restore.

- Fault isolation/Troubleshooting/Deferral.

- Servicing.

Developing a line operations safety assessment

Airlines interested in developing a LOSA can read more about the process in the sidebar below. The materials developed by the task force can be found on the FAA Web site (see fig. 3). These materials include LOSA posters, implementation guidance for management, observer training materials, observation forms, and database software.

Figure 3: The LOSA section of the FAA Web site

Airlines can download forms and software for implementing a ramp or maintenance LOSA from the FAA Web site.

Summary

Effective management of threats is a decisive factor in reducing the severity of errors. LOSA is a positive means for identifying threats and managing them before safety margins are reduced below acceptable levels. The result is a safer operation. Forms, training materials, implementation guidance, and software for use in developing a ramp LOSA and a maintenance LOSA are available online.

Here are general guidelines for implementing a LOSA for ramp or maintenance operations.

- Form an initial development team/LOSA steering committee made up of management, safety staff, and ramp or maintenance staff. This team will handle planning, scheduling, observer support, and data verification.

- Gather information from other companies that are using ramp LOSA or maintenance LOSA and get their input on benefits, their process, and implementation issues (see A4A or FAA Web sites).

- Identify problem areas to observe.

- For ramp LOSA, determine how many airplane turns to observe and where. For maintenance LOSA, determine the type and number of maintenance tasks to observe.

- Schedule observation dates and select observers.

- Develop or modify the observation forms (e.g., to use airline-specific terminology).

- Train all ramp or maintenance staff on ramp LOSA or maintenance LOSA and its characteristics.

- Train observers.

- Perform observations.

- Perform data verification.

- Analyze data.

- Write report and give to the steering committee, management, and relevant training, standards, and safety organizations. The report is to list problems, not solutions.

- Develop interventions, including enhanced policies, procedures, training, or equipment, based on the findings.

Materials to implement ramp LOSA and maintenance LOSA are available at no charge on the FAA Web site. The materials include LOSA posters, implementation guidance for management, LOSA observer training materials, LOSA observation forms, and LOSA database software.