The Boeing 747‑8 includes a new environmental control system (ECS) that integrates the air supply control system and the cabin air-conditioning and temperature control system.

By André Brasseur, Service Engineer;

Will Leppert, Service Engineer; and

Alexis Pradille, Service Engineer, Liebherr Technical Services

The new ECS on the 747-8 takes advantage of new technology to offer greater capacity, increased efficiency, and improved maintainability.

The 747-8 ECS increases cooling capacity and improves performance and maintainability, while providing a common 747 platform with simplified flight deck interfaces.

The system’s architecture integrates more functions in fewer line replaceable units (LRUs) to maximize efficiency and reliability and to simplify troubleshooting.

This article provides an overview of the design of the 747-8 ECS and in-service support.

Performance and reliability

A robust ECS is important for cabin safety and comfort. The 747-8 uses an ECS that offers digital control, lighter weight, increased reliability, and reduced maintenance compared to earlier technology. Changes to the air supply control system (ASCS) and cabin air-conditioning and temperature control system (CACTCS) combine to provide the 747-8 greater cooling capacity as well.

The 747-8 ECS uses new technologies to improve performance. These include an integrated air system controller (IASC) and the associated software. In addition, the system uses high-pressure water separation to dry out the air within the air cycle machine upstream of turbine section input, as well as pressure sensors to provide input to the IASC for icing control.

Combined, these technologies help improve the efficiency and reliability of the system, allowing for increased efficiency of bleed air and a reduction in bleed air penalties. That, in conjunction with the improved maintainability achieved through the placement of LRUs and LRU components, helps reduce operating and maintenance costs.

Other key improvements in the new ECS include an advanced new bleed system and true subfreezing packs.

Advanced bleed system

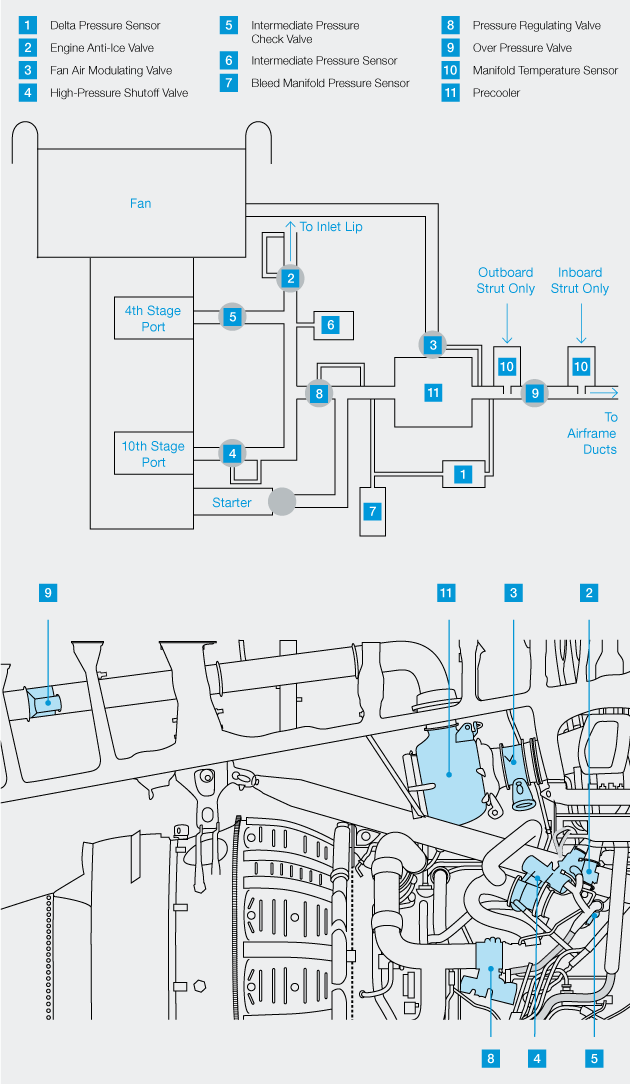

The 747-8 airplane is powered by General Electric GENX-2B engines. The engine bleed systems supply air from the engine compressor. There are four identical engine bleed systems per airplane with independent control and indication for each system (see fig. 1).

Figure 1: 747-8 engine bleed system

The system schematic (top) and component locations (bottom) in the 747-8 engine bleed system.

The air temperature and air pressure are regulated before being delivered to airplane systems. The bleed air is used for CACTCS, engine anti-ice, wing anti-ice, the hydraulic air-driven pump, the leading-edge flap drive unit, the nitrogen generation system, aft cargo heat, total air temperature probe aspiration, and hydraulic reservoir pressurization. All four engine bleed systems are connected by a common manifold.

Technological advancements enabled Boeing to make several improvements to the bleed system on the 747-8. These improvements include:

- New digital bleed. The system has no mechanical position switches and reduced use and consolidation of sensors.

- No remote valve controllers. The torque motor and solenoid are built into the valve design, allowing for easier troubleshooting and improved fault isolation.

- Fewer servo/sense lines. This increases system reliability.

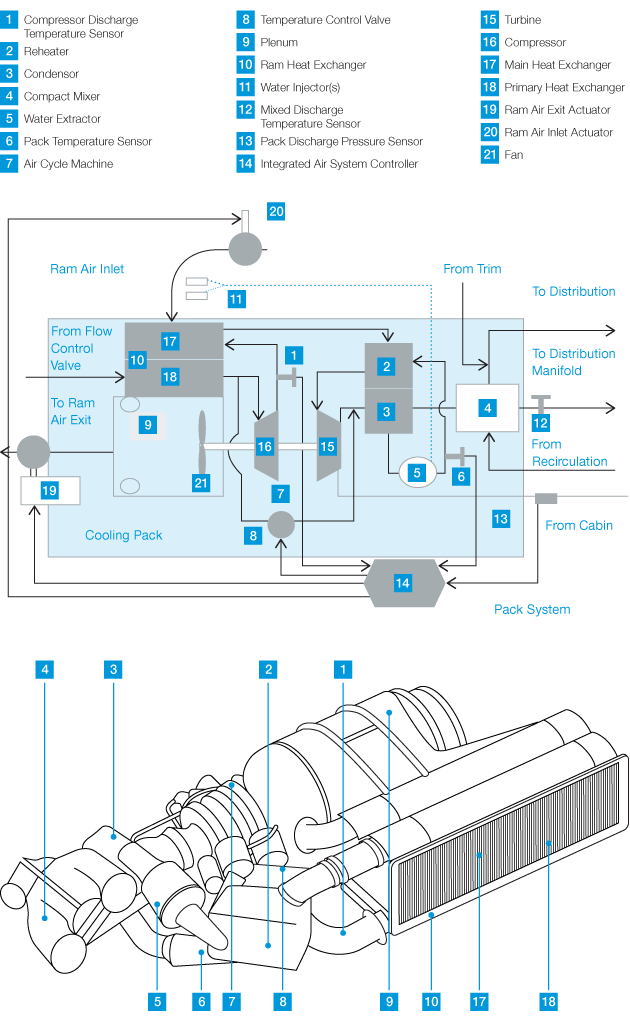

747-8 subfreezing pack

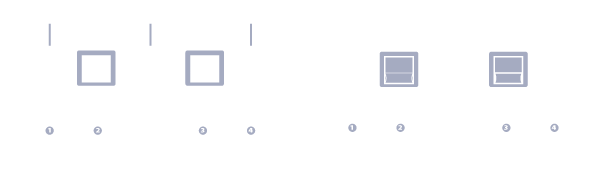

The 747-8 air-conditioning pack has several key features that allow it to be classified as a true subfreezing pack, which will operate to temperatures below the freezing point of water at all altitudes (see fig. 2). While earlier air-conditioning packs can drive subfreezing during all conditions, there are limitations that need to be placed upon the system due to the operating environment and the technology implemented within the system. As a result, below 25,000 feet (7,620 meters), where environmental icing is a factor, the pack turbine discharge (i.e., pack outlet) is limited to approximately 35 degrees F (1.67 degrees C) prior to mixing of recirculated air in the main distribution plenum. At cruise, where icing concerns are not a critical issue for operation, many packs do drive subfreezing as conditions warrant.

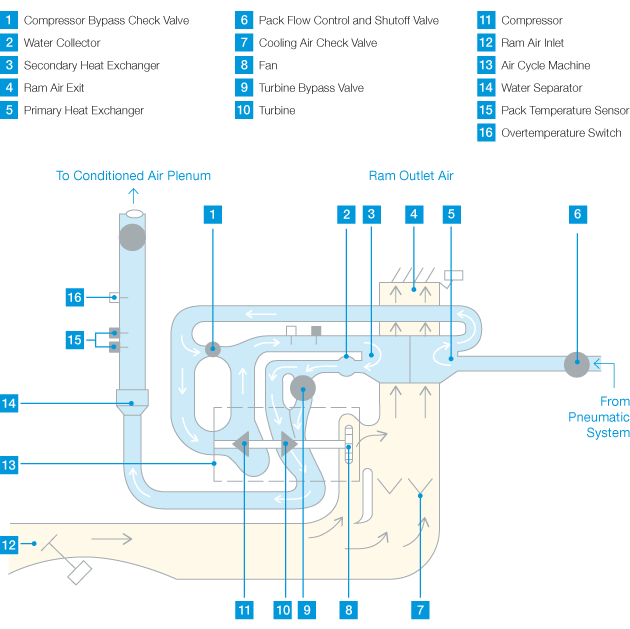

Figure 2A: 747-400 air-conditioning pack system

Compare this 747-400 to the 747-8 air-conditioning pack system shown in figure 2B. Note the locations of the respective water separator/extractor systems as well as the pack temperature sensor relative to the mixer discharge temperature sensor.

Figure 2B: 747-8 air-conditioning pack

A diagram of the 747-8 air-conditioning pack system.

The 747-8 pack incorporates technology that enables it to function as a subfreezing conditioned air supply during all phases of operation, both on the ground and in flight. Key factors that enable this technology to overcome environmental limitations include the use of:

- High-pressure water separation, which mitigates the buildup of ice within the air cycle machine (ACM).

- Integrated pack control features that mitigate ice formation within the air-conditioning pack.

- A compact mixing section at the turbine outlet of the pack, which allows recirculated air from the airplane ambient environment to be mixed directly with pack outlet air prior to implementing outlet discharge temperature limitations.

High-pressure water separation. The air-conditioning pack incorporates a water extraction loop within the pack to extract water and avoid ice formation at the ACM turbine outlet. This is accomplished by routing the air appropriately within the pack; water separation is accomplished within the pack itself as part of the air-conditioning process.

Air that has been heated in the ACM compressor section is first cooled by the main heat exchanger. The air is then further cooled below its dew point as it travels through the condenser section. Within the condenser section, water droplets are formed, allowing water to be removed from the system.

The water extractor then removes the water particles from the high pressure in the ACM by creating a vortex, which forces the water to collect at the walls of the unit. The dried air then passes into the reheater, where the air is again raised to the temperature of the air entering the water extraction loop before entering the ACM turbine inlet.

The water that is removed is then injected into the ram heat exchanger cooling air inlet by means of the water injectors to increase cooling efficiency of the ram air subsystem. This functionality is particularly critical for ground operations.

Integrated pack control. The pack temperature is modulated using the ram air door actuators (RADAs) and the temperature control valve (TCV). The RADAs modulate the ram air flow to regulate ACM compressor outlet temperature.

The TCV position controls the amount of hot air that bypasses the turbine, allowing it to adjust the ACM speed and subsequent pack discharge temperature downstream of the water extractor prior to flow injection into the ACM turbine section.

The ability to adjust this temperature in conjunction with the necessary components and controls to sense flow restrictions associated with ice buildup within the ACM enables the system to avoid and control ice formation within the condenser. In addition, the ability to control the temperature within this stage of the ACM operation increases the efficiency and performance of the high-pressure water extraction process.

The components and technology provided within the ACM allow the unit to function as a cooling unit with increased capacity due to the use of a “defrost cycle,” as required to mitigate the presence of ice. This protects the pack against the damage that could be caused by ice buildup within the ACM. Because of this capability, the 747-8 pack can safely operate below freezing and provide increased cooling capacity during all operating conditions.

Compact mixing section. The pack discharge air from the ACM turbine section is then sent to the compact mixer prior to distribution into the main airplane cabin area. The compact mixer ensures the efficient mixing of outside air delivered by the ACM with recirculated air from the main cabin zones. Consequently, rather than controlling the pack discharge temperature downstream of the turbine directly, the compact mixer outlet temperature is controlled according to the following schedule, which is strictly based on altitude:

- From 0 to 25,000 feet (0 to 7,620 meters), control the minimum outlet temperature to 37 degrees F (3 degrees C).

- From 25,000 to 30,000 feet (7,620 to 9,144 meters), control the minimum outlet temperature linearly from 37 degrees F (3 degrees C) at 25,000 feet (7,620 meters) to 29 degrees F (‑2 degrees C) at 30,000 feet (9,144 meters).

- Above 30,000 feet (9,144 meters), control the minimum outlet temperature to 29 degrees F (‑2 degrees C).

In this way, the compact mixer allows the turbine discharge temperature to float well below freezing to directly address the air-conditioning load imposed by the recirculated air from the main cabin zones and allows the pack to provide more of its available capacity as a result. For example, during hot-day ground conditions with very warm recirculated air injection, the pack has the capacity to drive cold, as necessary, to maintain a temperature above 37 degrees F (3 degrees C) at the discharge downstream of the compact mixer section.

Familiar flight deck interfaces

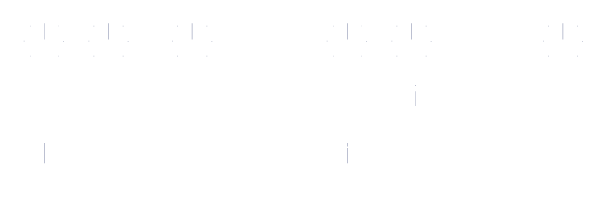

The monitoring and control functions of ASCS and CACTCS are integrated in centralized software that is fit into three interchangeable digital controllers. System control has been managed to keep a flight deck interface similar to the 747-400 (see fig. 3).

Figure 3: 747-400 and 747-8 interface similarity

Flight deck controls for the new environmental control system are very similar to those on the 747-400, easing the transition to the new airplane for flight crews.

New approach to in-service requests

The new 747‑8 ECS also represents a new way of managing in-service requests designed to provide operators with the fastest possible response. In-service requests will be coordinated closely with Liebherr-Aerospace, the supplier of key components in the system. The Liebherr-Aerospace Customer Support & Services network deployed for the 747‑8 includes spares, repair, and field support services stationed in China, France, Germany, Russia, Singapore, United Arab Emirates, and the United States. A Liebherr-Aerospace field service representative will work closely with customers.

Liebherr will also be available to help respond to in-service requests. Customers can send support service requests to Boeing or contact Liebherr’s field service engineering staff directly.

Summary

The new ECS on the 747‑8 takes advantage of new technology to offer greater capacity, increased efficiency, and improved maintainability while maintaining a flight deck interface similar to that on the 747‑400. In-service requests will be coordinated closely with Liebherr-Aerospace, the supplier of key components in the system.

For more information, please contact André Brasseur.