Working exclusively with Fujitsu and a major U.S. airline, Boeing has developed, tested, and validated the airline industry’s first comprehensive radio frequency identification device (RFID) and contact memory button (CMB) technology for commercial airplanes. This system can significantly reduce an airline’s operating costs by eliminating untimely, labor-intensive maintenance while providing easy access to maintenance histories.

By Phil Coop, Program Manager, RFID Integrated Solutions

Operators can reduce costs and inspection time, eliminate labor-intensive maintenance, and provide easy access to maintenance histories.

Boeing’s RFID Integrated Solutions system employs unique tools such as RFID and CMB to automatically identify, track, and manage critical airplane parts. It is a comprehensive solution for a series of integrated technologies and maintenance process improvements that can help airlines improve their overall maintenance efficiency and performance.

By providing a comprehensive, turnkey solution, RFID Integrated Solutions eliminates the need and long lead time for operators to retrofit their fleets with automated identification technology themselves.

This article provides an overview of RFID Integrated Solutions and offers examples of how its use can save airlines time and reduce errors.

A better way to manage airplane components

RFID Integrated Solutions combines RFID tags and CMBs installed on parts and components throughout an airplane. RFID is an automated identification technology that uses radio frequency waves to transfer data between a reader and items that have RFID devices, or tags, affixed. The tags contain a microchip and antenna, and operate at internationally recognized standard frequencies. The RFID tag is similar to a bar code but offers significant advantages. The RFID tag stores data and offers enhanced data collection, the ability to read without a direct view of the RFID label, a dynamic read/write capability, simultaneous reading and identification of multiple tags, and tolerance of harsh environments. CMBs are another form of automated identification technologies (AIT) used in this offering. There is significantly more information in a CMB, which is easily accessed by direct contact.

Information — such as part and serial numbers, manufacturing dates, and maintenance history — is stored on the tags and buttons. Technicians can use a handheld scanner to read and update the RFID information wirelessly. This information then becomes an electronic record that travels with the airplane. RFID Integrated Solutions is the first fully integrated airborne automated identification technology program in commercial aviation.

RFID Integrated Solutions uses two distinct but related technologies to store and retrieve information about parts and components:

Low-memory RFID. These 512-bit to 1-kilobyte devices are used to store configuration, presence, security, and serviceability data. This data may include part and serial numbers, date of manufacture, expiration date, and location on the airplane.

High-memory RFID and CMB. These devices range in capacity from 8 kilobytes to 4 gigabytes and are used to store point-of-use lifecycle data about a part, component, or section of the airplane, including:

- Birth record. Pedigree and identity.

- Current record. Change in configuration, identity, or characteristics (such as hazardous materials or weight).

- Maintenance history. Actions taken and conditions noted; change in custody, accountability, and location; utilization and consumption; trends (such as no fault found).

- Scratch pad. Rewritable section that technicians can use to enter text or store photos or videos.

The initial deployment of RFID Integrated Solutions is focused on five areas. These areas were selected based on Boeing consultation with airlines on the operational needs of airlines during the development process of the RFID Integrated Solution system:

- Emergency equipment management (e.g., life vests, oxygen generators).

- Rotables management.

- Repairables management.

- Structural repair and airframe degradation management.

- Essential cabin items (e.g., carpet panels, floor panels, insulation blankets, seat covers, linens, and tapestries).

Emergency equipment management

The objectives of emergency equipment management include confirming that assets are present and where they should be, and that they are serviceable, not expired, or have not reached the threshold for time of expiration. RFID Integrated Solutions enables technicians to gather this information simply by walking through the airplane cabin with an RFID scanner. Seats, bins, compartments, and other areas where equipment is stored illuminate green on the scanner if the component is present and serviceable and red if it is missing, expired, or has been tampered with (see fig. 1).

Figure 1: Radio frequency identification device (RFID) scanner

By providing an easy-to-read view of emergency equipment within an airplane cabin, Boeing’s RFID Integrated Solutions system eliminates the need for technicians to open and close compartments and use mirrors and flashlights, which adds time and can result in inaccurate data.

RFID Integrated Solutions results in tremendous time savings. For example, it can reduce life-jacket inspection time by up to 85 percent and oxygen generator inspection time by up to 99 percent (see fig. 2). It can also reduce oxygen generator inventory by more than 50 percent and extend the generator lifecycle by up to 20 percent.

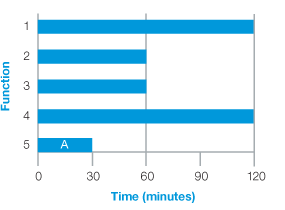

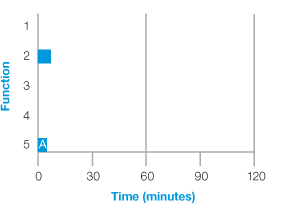

Figure 2: 777 oxygen generator inspection

RFID Integrated Solutions reduces the time required for a 777 oxygen generator inspection from six and a half hours to 15 minutes, which represents a reduction of more than 90 percent.

| 777 O2 General Inspection Before: 6.5-Hour Task |

777 O2 General Inspection After: 15-Minute Task |

||||

|

|

||||

|

A | Value-Added (VA) Task: Queue Time = 360 mins Touch Time = 30 mins Total Lead Time = 390 mins (VA =~10%) |

|

A | Value-Added (VA) Task: Queue Time = 10 mins Touch Time = 5 mins Total Lead Time = 15 mins (VA = 33%) |

Rotables management

The rotables management component of RFID Integrated Solutions enables operational efficiency across the entire rotable component value stream by bringing critical decision-making data to the point of use and unprecedented visibility to the supply chain. RFID Integrated Solutions can help reduce inventory and maintenance lead time, improve troubleshooting, and increase product integrity while providing more comprehensive asset management.

RFID Integrated Solutions provides technicians with complete information about rotable parts, including part number, birth record, and current record. A maintenance history section enables technicians to provide information such as when the part was installed, removed, or modified. Conditions such as leaks, noise, and extreme temperatures can also be noted directly on the part’s RFID tag. Information stored on the tags can enhance parts traceability and reduce cycle time to solve in-service problems by improving the accuracy of information exchanged between airlines and parts suppliers. All readers include the writing function as well.

The tag also provides technicians with up to 500 characters of free text that can be used to make more meaningful notes than are possible on the U.S. Federal Aviation Administration Form 8130-3 currently used. As parts travel through the supply chain, RFID Integrated Solutions makes it easy to see when they were shipped, received, and stored using a proprietary process to identify value-added information for each customer.

Repairables management

An RFID Integrated Solutions repairables management system can reduce queue time by up to 98 percent and dramatically improve parts utilization by giving operators increased visibility into their repairables supply chain.

In a typical scenario, a CMB is attached to a part and preloaded with information about that part. Simply by reading the CMB, a technician can determine that the part is repairable and which shop is responsible for repairs. Alerts can be incorporated that, for example, inform the supply chain that a repairable part has been removed and is on its way to the repair shop.

While developing RFID Integrated Solutions, Boeing found that some repairable parts at one airline had a lead time averaging 431 days. The re-engineered process enables parts to move through the supply chain in just 12 days, a reduction of 97 percent. During the analysis, one airline discovered 87 instances of the same part in the queue — and had actually ordered three new replacement parts, not realizing it already had 87 repaired parts available.

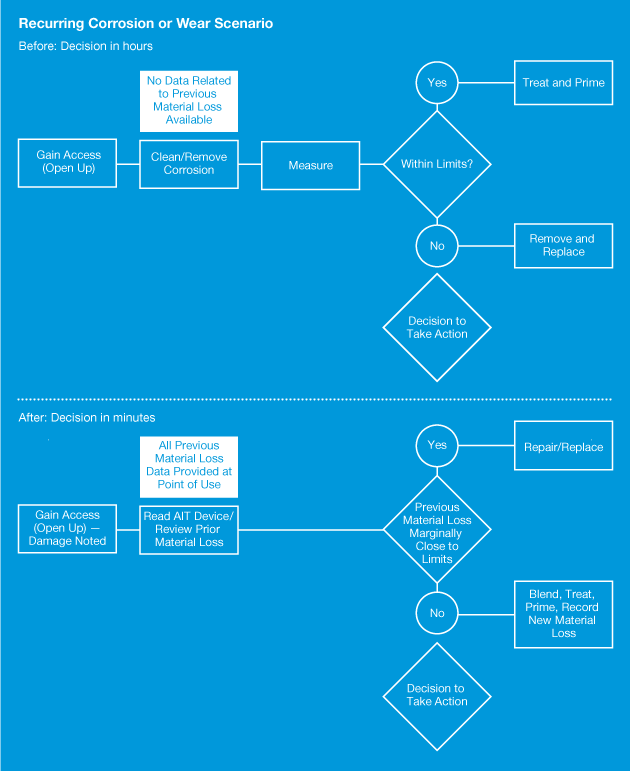

Structural repair and airframe degradation management

RFID Integrated Solutions can streamline heavy maintenance by enabling mechanics to use CMB tags to record all pertinent data about a structural repair, enabling the data to be located and reviewed easily during subsequent maintenance (see fig. 3). This is particularly valuable for composite structures and hidden repairs.

Figure 3: Structural repairs and airframe degradation management system

With the traditional approach to structural repairs, mechanics can spend hours removing corrosion and waiting for inspection only to find that material removal has exceeded limits. RFID Integrated Solutions enables mechanics to read an affixed AIT device (installed in corrosion-prone areas and based on previously defined threshold) and make a decision to replace the part before wasting hours of time treating and inspecting.

The application allows users to scan and store up to 4 gigabytes of data, including photos, PDF copies of repair orders, and recurring inspection requirements. By providing relevant data at the exact point of the repair, RFID Integrated Solutions can reduce the time required to make a repair decision by up to 99 percent. Other benefits include:

- Structural repairs. Capture damage information for the repair, including photos of damage and damage removal.

- Component repairs. Capture unique repairs and modifications, including photos and drawings.

- Corrosion prevention and control program. Capture previous corrosion removal and material loss directly at the point of high corrosion-prone areas.

- Aging airplanes. Capture records of repairs in critical zones.

RFID Integrated Solutions will provide richer and more frequent information about airplane components. The supporting documentation maintained by RFID Integrated Solutions will make it easier to sell or purchase an airplane.

Essential cabin items

By providing a simple, fast way to determine the replacement history for large bulk cabin items (such as carpet panels, floor panels, insulation blankets, and seat covers), RFID Integrated Solutions enables maintenance personnel to remove only what is required (see fig. 4). This can extend the lifecycle of the items, reduce wash times, extend life of fire-resistant materials, and reduce lead time and hazardous waste removal.

Figure 4: Cabin interiors

RFID Integrated Solutions can mean a significant reduction in linens and tapestries — as much as 25 percent per ship set exchange. That can reduce inventory requirements as well.

This same approach can be used to track the maintenance history of freighter interior items, such as cargo loading system components, fire suppression systems, and interior trim.

Tailored approach

Because each airline’s requirements are unique, Boeing will tailor RFID solutions for each customer’s needs; provide automated identification technology tag readers and software applications; integrate those solutions into the customer’s operational environment; and establish a long-range plan that will expand automated identification technology solutions across the customer’s enterprise.

A fleet retrofit to incorporate RFID Integrated Solutions can be integrated into the airline’s current maintenance schedule. Emergency equipment retrofits can be accomplished during an overnight check. Boeing provides retrofit kits, instructions, and technical oversight. No supplemental type certificate is required, and installation methods have received regulatory approval.

Boeing also provides a comprehensive training system that includes literature; syllabus; training aids and simulators; on-site, hands-on training; and a train-the-trainer program. Instructors are former airline engineering and maintenance staff with experience in both the RFID/CMB technology and airline operations.

Summary

Operators can reduce operating costs; reduce inspection time; eliminate untimely, labor-intensive maintenance; and provide easy access to maintenance histories with the airline industry’s first comprehensive RFID and CMB technology for commercial airplanes. The system, developed by Boeing and Fujitsu, automatically identifies, tracks, and manages critical airplane parts, improving maintenance efficiency and performance.

For more information, please contact Phil Coop.