Accidents involving the current generation of commercial airplanes are rare but offer important insights into advancements in the safety and crashworthiness of airplane design. These advancements reflect decades of innovation and targeted efforts to improve survivability in an airplane accident, especially during takeoffs and landings.

By Alan J. Anderson, Payloads Engineering Chief Engineer (Retired), Interiors-Payloads System Engineering

Ongoing work with regulators has resulted in interiors that are designed to increase the survivability of accidents that occur during takeoff or landing.

The accident fatality rate for jet airplanes has fallen dramatically during the last 50 years. This decrease is due in part to continuing efforts by airplane manufacturers and regulators to use information gained from accidents to develop safer, more survivable airplanes.

This article provides examples of significant interior enhancements to Boeing airplanes and how they enhance airplane safety, particularly during accidents that occur during takeoffs and landings.

A history of improving airplane interiors

Since the first passenger airplane was introduced in the 1930s, airplane manufacturers have worked to make airplanes safer for the passengers and crew who fly in them (see fig. 1). For example, Boeing has worked continuously to enhance the safety of its products and to lead the industry to higher levels of safety through global collaboration.

Figure 1: Airplane interiors over time

Boeing airplane interiors have become both more comfortable and safer over time.

|

|

|

| Boeing 247 (1933) | Boeing 707 (1958) | |

|

||

| Boeing 787 (2011) | ||

By working together, regulators, operators, and manufacturers can maximize safety by sharing knowledge and targeting safety efforts to address areas with the most risk.

Some recent events highlight the safety of today’s passenger jet airplane interiors during takeoff and landing accidents.

- In December 2008, an airplane crashed while taking off, ending up on fire in a 40-foot-deep ravine several hundred yards from the runway. There were no fatalities among the 115 passengers and crew, even though the metal fuselage had been breached by fire.

- In December 2009, an airplane carrying 154 passengers and crew overran the runway during a landing in heavy rain and broke apart. There were no fatalities.

- In August 2010, an airplane crashed while attempting to land during poor weather, breaking into three pieces on impact. There were 125 survivors among the 127 passengers and crew aboard the flight.

The industry’s work on airplane safety and survivability of airplane interiors emphasizes three areas: surviving impact, surviving a fire, and evacuation.

Surviving impact

Survivability is greatly influenced by seat design. The greater the ability of airplane seats to remain in place and absorb energy during an impact, the greater the likelihood of passenger survival. In addition, the seat back is designed to protect passengers behind the seat from head injury.

Seat design. In the 1930s, passenger airplane seats could withstand a static force six times the force of gravity (6g). For commercial jet airplanes beginning in the 1950s, the 6g requirement was raised to 9g. Today’s seats are required to withstand a 16g dynamic force. A 16g seat is tested in a manner that simulates the loads that could be expected in an impact-survivable accident. Two separate dynamic tests are conducted to simulate two different accident scenarios: one in which the forces are predominantly in the vertical downward direction and one in which the forces are predominantly in the longitudinal forward direction. The highest load factor is in the forward direction at a force of 16g.

Head injury protection. Where head contact with seats or other structure can occur, Boeing provides protection so that the head impact does not exceed the head injury criterion (HIC) established by the U.S. Federal Aviation Administration (FAA). HIC measures the likelihood of head injury resulting from an impact. Compliance with the HIC limit is demonstrated during a dynamic sled test that includes a 50 percent male-size test dummy, the seat, and any airplane structure that could be impacted by the occupant’s head.

Surviving a fire

In 1985, the FAA developed a new test standard for large surface area panels, such as ceilings, walls, overhead bins, and partitions. The standard required that all commercial airplanes produced after August 20, 1988, utilize panels that exhibit reduced heat and smoke emissions, delaying the onset of a flashover (i.e., the simultaneous or near-simultaneous ignition of all flammable material in an enclosed area). Interiors are updated and refurbished many times during the life of an airplane. This results in interiors that incorporate these enhancements even in older airplanes.

In addition, airplanes manufactured on or after August 20, 1990, must comply with definitive standards of a maximum peak heat release rate of 65 kilowatts per square meter, a maximum total heat release of 65 kilowatt minutes per square meter, and specific optical smoke density of 200 (i.e., the OSU 65/65/200 fire safety standard defined by Ohio State University).

Extensive fire protection systems are also part of every Boeing passenger airplane. These systems include the use of fire-protective materials, smoke detection and fire extinguishing systems, and insulation blankets designed to resist burn-through from a fuel fire next to the bottom half of the fuselage. (For more information on passenger compartment fire protection, see Fire Protection: Passenger Cabin in this issue of AERO.)

Evacuating the airplane

The FAA requires that an airplane can be evacuated of all passengers in 90 seconds. Boeing airplane interiors include a number of features to facilitate this process (see fig. 2). These features include floor proximity lighting and escape slides.

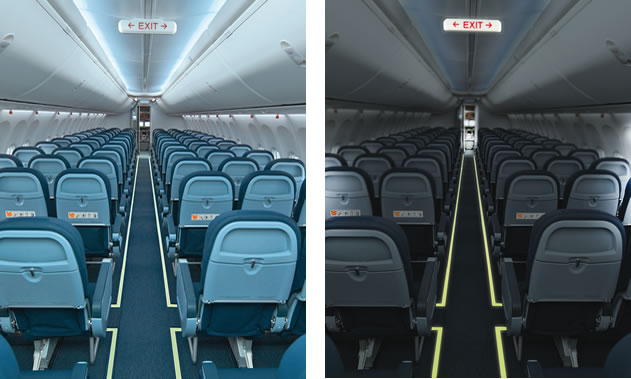

Figure 2: Design features key to rapid evacuation

Because evacuating an airplane quickly greatly increases survivability rates, all Boeing airplanes include a number of features designed to enable evacuation within 90 seconds.

Floor proximity lighting. When passengers evacuate after a crash, buoyant hot smoke and gases can fill the cabin down to near floor level, obscuring overhead lighting. Evacuation is improved through the use of lights, reflectors, or other devices to mark the emergency escape path along the floor. The FAA determined that floor lighting could improve the evacuation rate by 20 percent under certain conditions. As a result, the U.S. commercial fleet was retrofitted with floor proximity lighting by 1986, marking the completion of a two-year compliance schedule (see fig. 3). The 777 was the first Boeing airplane to include floor proximity lighting in production models.

Figure 3: Floor proximity lighting

Floor proximity lighting aids airplane evacuation under dark or smoky conditions.

Escape slides. Boeing passenger airplanes are equipped with automatic, self-inflating slides that are made of fire-resistant materials that become rigid after being deployed. (For information about the evolution of escape slides, see below.)

Summary

Boeing has worked with regulators, operators, and industry to continually enhance the safety of its airplanes. This ongoing work has resulted in interiors that are designed to increase the survivability of crashes that occur during takeoff or landing.

For more information, please contact Air Safety Investigation.