The engines and auxiliary power units (APUs) on Boeing airplanes incorporate extensive measures for fire protection, including fire detection and extinguishing systems.

By Sham Hariram, Technical Fellow, Boeing Propulsion Engineering;

Paul Philipp, Senior Propulsion Engineer, Boeing Propulsion Engineering; and

Dave Dummeyer, Associate Technical Fellow, Boeing Propulsion Engineering

Because of the importance of engines to safe flight, it is critical that they incorporate extensive and reliable fire-protection systems.

This article is the first in a series exploring the implementation of fire protection on transport category airplanes.

Fire protection is given one of the highest considerations at Boeing in airplane design, testing, and certification.

In designing an airplane’s fire protection systems, Boeing uses the principles of separation, isolation, and control. These principles involve separating the three essentials for creating a fire (i.e., fuel, ignition source, and oxygen), isolating potential fires from spreading to other parts of the airplane, and controlling a fire should one occur.

To effect this separation, isolation, and control, Boeing uses both passive and active systems. Passive systems include the use of noncombustible or self-extinguishing materials; separation by routing, compartmentation, isolation, ventilation, and drainage; and bonding and grounding. Active systems include fire and overheat detection systems, fire-extinguishing systems, temperature sensing, air and fuel shut-off means, and automatic shutdown of nonflight critical systems. Fire protection systems on Boeing airplanes meet all aviation regulatory requirements as well as internal Boeing design requirements.

Because of the importance of engines to safe flight, it is critical that they incorporate extensive and reliable fire-protection systems. The APU utilizes similar systems. This article describes how Boeing provides fire protection for the engine pods, also termed “engines,” and for APUs. An engine pod consists of the engine, the inlet, the nacelle, the thrust reverser, the exhaust section, and the strut or pylon.

Passive fire-protection systems

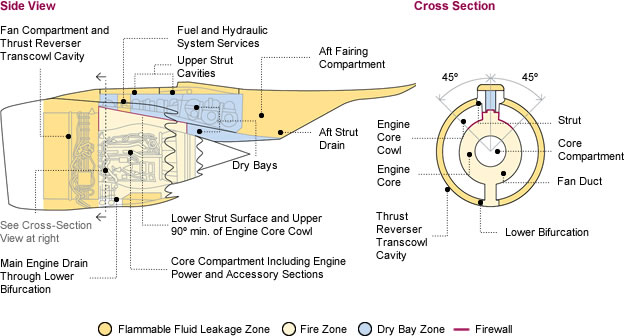

Engine zones. The engines and strut or pylon structures on Boeing airplanes form compartments, each of which is isolated by basic structure and ancillary surfaces. Each engine nacelle or strut compartment is designated as a zone, such as fire zone, flammable fluid leakage zone, or dry bay zone, according to the potential for the presence of flammable fluids and ignition sources (see fig. 1).

Figure 1: Compartmentation in a typical engine pod

Engine pods incorporate zones designed to minimize the probability of a fire and to isolate a fire, should one occur.

Only the compartments that contain ignition sources and the potential for flammable fluid leakage are classified as fire zones. Examples are the engine case around the compressor, combustor, and turbine sections of the engine. The gearbox and its accessories are also considered potential ignition sources during failure conditions that could cause temperatures to exceed the auto ignition temperatures of fluids that may be present in the compartment. The areas adjacent to the engine fire zone — such as the engine fan compartment, strut or pylon, and strut heat shield — are isolated by firewalls. Other compartments are isolated by bulkheads and vapor barriers. Boeing mitigates fire hazards in engine and nacelle compartments by:

- Minimizing the potential for ignition.

- Using compartmentation and isolation.

- Routing flammable fluid-carrying lines away from electrical wires and hot pneumatic ducts.

- Using nonflammable construction materials.

- Utilizing firewalls.

- Providing a means for detecting and extinguishing fires in fire zones.

- Providing a shut-off means for flammable fluids into and out of the fire zone.

- Minimizing the accumulation of flammable fluids and vapors through the use of drainage and ventilation.

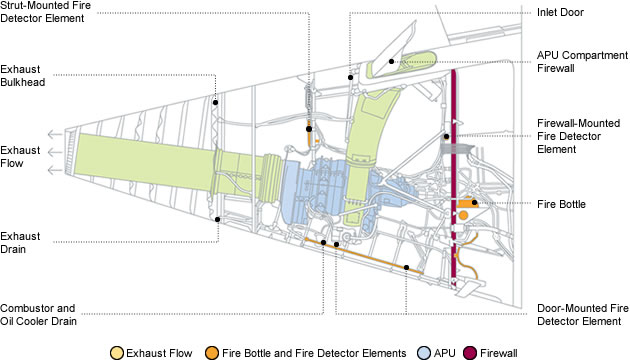

APU compartment. The APU compartment is by definition a fire zone (see fig. 2). It is isolated from the rest of the airplane by a firewall. The APU installation uses the same fire hazard mitigation principles as the engines listed above, plus:

- Automatic shutdown of the APU.

- Automatic shutoff of air source.

Figure 2: A typical APU compartment

The APU compartment firewall isolates the APU from the rest of the airplane.

Flammable fluid drainage. The engine nacelle and APU installations are designed to drain flammable fluids overboard. These drainage provisions include drain holes, hoses, and tubing for capturing and safely discharging flammable fluid leakage overboard.

Ventilation. In the engine pod, ventilation air is provided in fire and flammable fluid leakage zones to minimize the accumulation of flammable vapor. All ventilation flow is designed to exit safely without being reingested. In the engine core fire zone, controlled cooling flow provides a source of core ventilation. Some installations have dedicated ventilation inlets. The APU compartments are ventilated by either a mechanically driven fan or a passive eduction cooling system. Any flammable vapors are forced out through vent openings or through the eduction exhaust system. The airflow driven by either of these two systems prevents the accumulation of flammable vapors and provides cooling for hot surfaces.

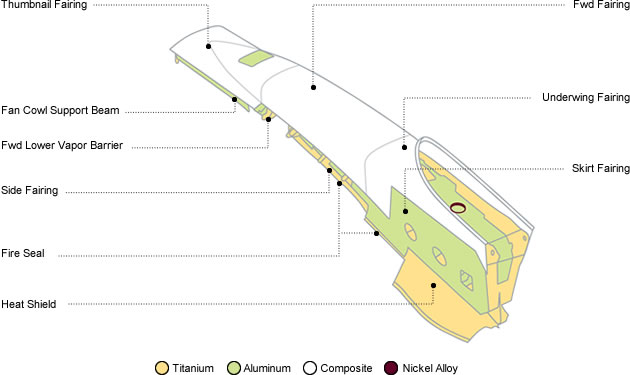

Firewalls. The strut and nacelle areas adjacent to the engine fire zones are isolated by a firewall extending from the engine fan frame to the exhaust nozzle (see fig. 3). For engines with fan compartment mounted gearbox and accessories, the entire fan cowl and thrust reverser inner cowling are designed to be fireproof for in-flight conditions. The upper quadrant of the fire zone compartment (typically +/- 45 degrees of the engine core compartment) will prevent burn-through to the adjoining strut and wing structures for the ground condition. In addition, fireproof feedthroughs, boots, seals, and sealants are used to seal penetrations and gaps on firewalls and barriers to prevent flammable fluid, vapor, or the propagation of fire to adjacent zones.

Figure 3: A typical strut or pylon

Strut structures incorporate numerous firewalls of various materials to isolate strut and wing areas adjacent to engine fire zones.

Most APU installations are located in the airplane tailcone outside of the pressure vessel or passenger compartment. This provides a high level of isolation. The APU compartment is further isolated from the forward sections of the airplane by a fireproof compartment firewall. Other APU installations not located in the airplane tailcone are in self-contained compartments with firewall structure surrounding them on all exposed sides within the airplane.

Bonding and grounding. All Boeing airplanes incorporate electrical bonding or grounding provisions for electrical system components and structure to protect against static electricity, sparking, or the arcing that occurs between surfaces resulting from electrical system faults or lightning strikes. The bonding or grounding prevents conditions that could ignite flammable vapors.

Explosion proofing. Electrical components installed in the fire or flammable fluid leakage zones are required to be explosion proof. In the event that flammable fluid or vapor seeps into a cavity of the component, it is required to contain the fire should the flammable fluid ignite. The components are also required not to overheat and become an ignition source. Each component type is tested in a laboratory environment to demonstrate that it meets these requirements.

Active fire-protection systems

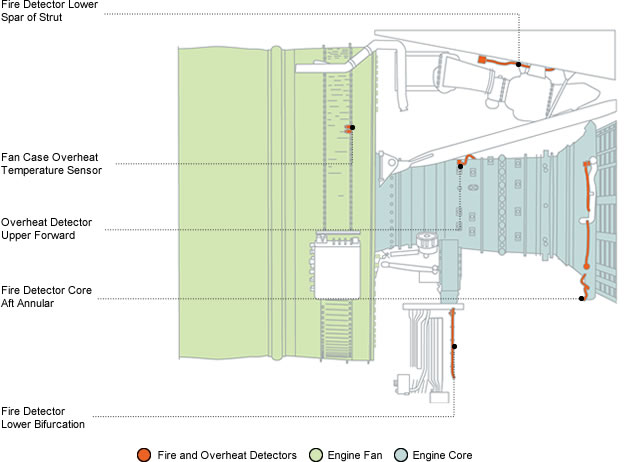

Engine fire detection. The typical engine fire-detection system includes both fire and overheat detectors (see fig. 4). Each detector location has two heat-sensing elements along with associated support tubes, brackets, and electrical connectors. Sufficient area coverage is required to ensure prompt detection of a fire within the fire zone. The detector elements of the fire- or overheat-detection system are configured to form two redundant loops, with each detector loop monitored by a separate control card or a controller. Signals from the detectors are processed through an automatic fire-and-overheat-logic-and-test system to generate flight-deck displays and aural warnings to alert the crew in the event of an engine fire. Alerts are displayed in the form of lights (i.e., a red MASTER WARNING for fire and an amber CAUTION for overheat), together with the simultaneous illumination of the associated engine-fire handle and fuel-shutoff switch for an engine fire. On airplanes with engine-indication-and-crew-alerting-system (EICAS) capability, EICAS messages are shown on the integrated flight-deck displays. An EICAS message also appears in the event of a detector system failure.

Figure 4: Typical engine fire and overheat detector locations

Nacelle compartments contain multiple fire or overheat detector elements.

APU fire detection. The typical APU fire-detection system consists of two or three detectors connected in series by airplane wiring, each with a redundant detector element (referred to as a detector loop) with both ends connected to the control card. The APU detection system uses the same type of detector elements, circuitry, operation, testing methods, and certification procedures as the engine fire-detection system. The fire detection system will automatically shut down the APU when a fire is detected. The fire detector assemblies are contained entirely within the APU compartment in locations selected to provide maximum coverage of the compartment where fire could occur and to ensure prompt fire detection.

APU fire-detection displays and controls are located on the flight deck. When a fire is detected, the APU fire handle illuminates, the MASTER WARNING lights illuminate, warning and status messages are displayed on EICAS, and the aural warning is activated. An external APU fire horn that is resettable from the flight deck (or from the APU fire/shutdown panel near the wheel well or away from the APU) is also provided.

Engine fire extinguishing. Engine fire-extinguishing systems consist of extinguishing-agent high-pressure bottles, distribution tubing, nozzles, and flight-deck controls and displays. Two fire-extinguishing-agent bottles containing Halon 1301 and interconnecting tubing are installed in a location where they can serve two engines, although there are airplane models that have two independent bottles serving each engine.

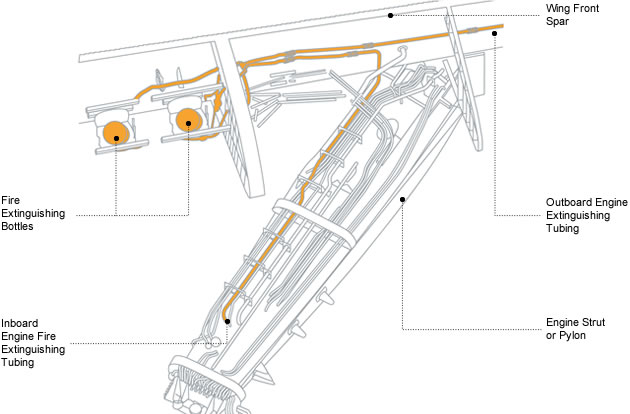

On some airplane models, the bottles are installed in the left and right wing leading edge (see fig. 5). On other models, they are mounted in the fuselage or in the strut or pylon. Each engine fire zone is required to be protected by two independent extinguishing-agent bottles, each capable of extinguishing a fire within the zone.

Figure 5: Engine fire-extinguishing system

On this airplane model, two fire-extinguishing-agent bottles and associated tubing are installed in the leading edge of each side of the wing.

APU fire extinguishing. The APU fire-extinguishing system located in the aft fuselage is a single-shot system provided to extinguish a fire in the APU compartment. The system consists of the extinguishing-agent bottle, distribution tubing, discharge nozzle, and necessary flight-deck controls and displays. The fire-extinguishing-agent bottle is located on the forward side of the APU firewall. The single discharge line directs agent to a nozzle located in the APU compartment.

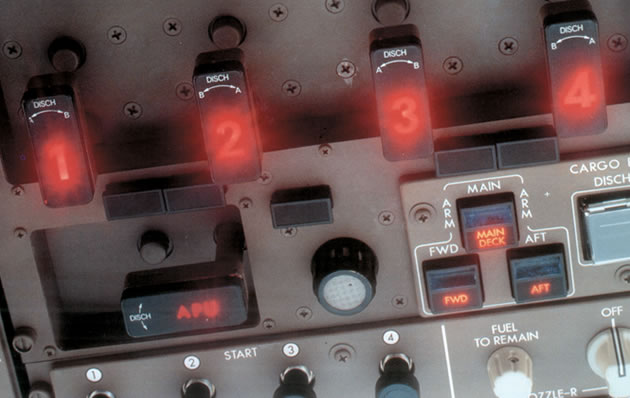

The APU-extinguishing-agent bottle design is similar to that of the engine. However, the APU bottle has a single discharge outlet rather than two, and the service pressure, amount of agent, and safety relief valve opening pressures differ. Some APU installations have options for a second APU bottle, for automatic fire extinguisher discharge, and for the use of an engine bottle in place of the standard APU bottle. The fire-extinguishing systems for both the engines and APU are controlled from the flight deck (see fig. 6).

Figure 6: Fire-extinguishing control

Controls for all airplane fire-extinguishing systems are located on the flight deck. This control module for the 747 shows controls for all four engines, the APU, and the cargo hold. The respective fire handle illuminates red if an engine fire condition is detected. Pulling the fire handle arms the fire-extinguishing system and shuts down the engine. It also shuts down the fuel furnished to that engine, the pneumatic system, the hydraulic system, and the electrical system associated with that engine. Rotating the fire handle discharges extinguishing agent into the engine.

Testing of fire protection systems and components

Boeing conducts airplane ground and flight testing of various aspects of the engine and APU fire-protection systems. Testing includes:

- Fire detection system.

- Fire-extinguishing-agent concentration.

- Fluid drainage, both on ground and in-flight.

- Temperature margin verification for fire detectors.

- Laboratory qualification of all system components.

- Laboratory fire tests for firewalls, feedthroughs, fire seals, installation components, and flammable fluid carrying components, in simulated installed conditions.

Summary

Boeing places the highest importance on designing and certifying fire protection systems on an airplane. The engines and APUs incorporate extensive fire protection, including detection and extinguishing systems.

For more information, please contact Sham Hariram.